The Team

Based in Malibu, CA, HRL Laboratories is one of the world's premier research laboratories, working on projects for General Motors, Boeing, and the U.S. Government. HRL is divided into several laboratories, each focusing on technologial development in distinct fields. This project is contained within the Architected Materials division of the Materials & Microsystems Laboratory.

My Role

I interned within the Architected Materials division of the Materials & Microsystems Laboratory during the summers of 2022 and 2023.

Project Overview

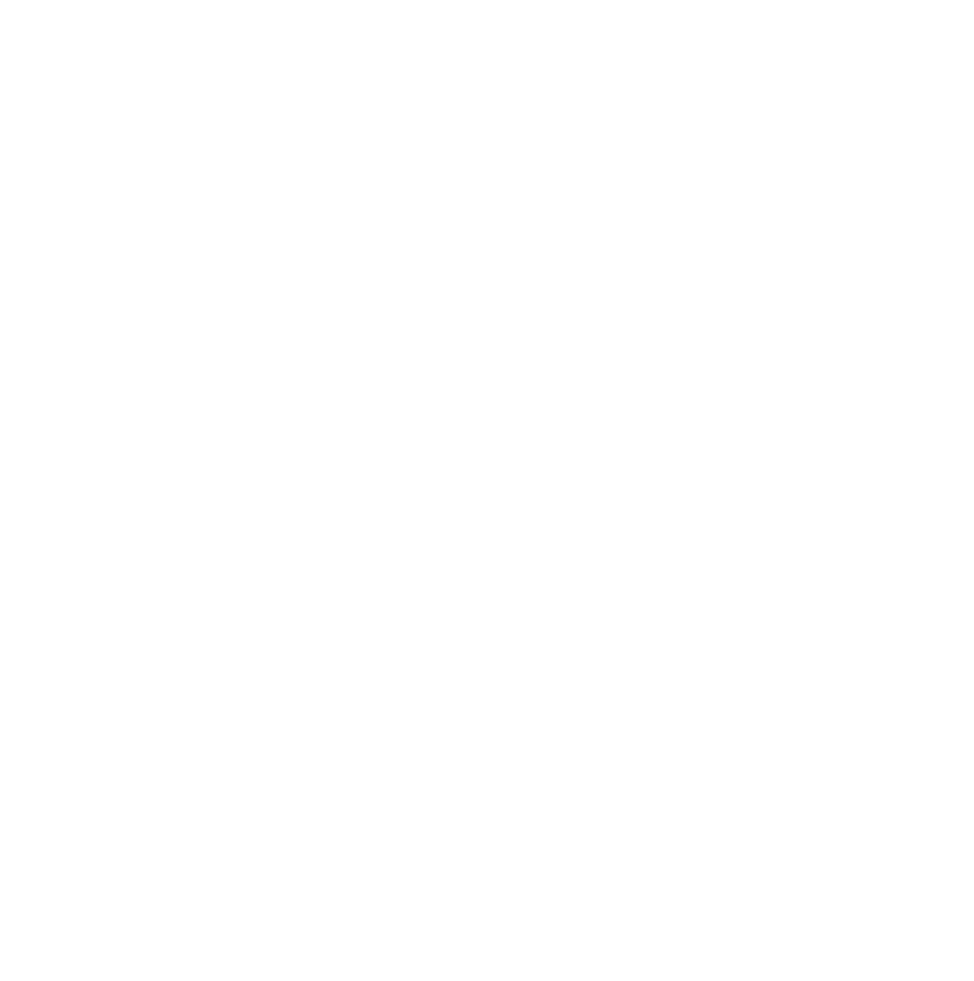

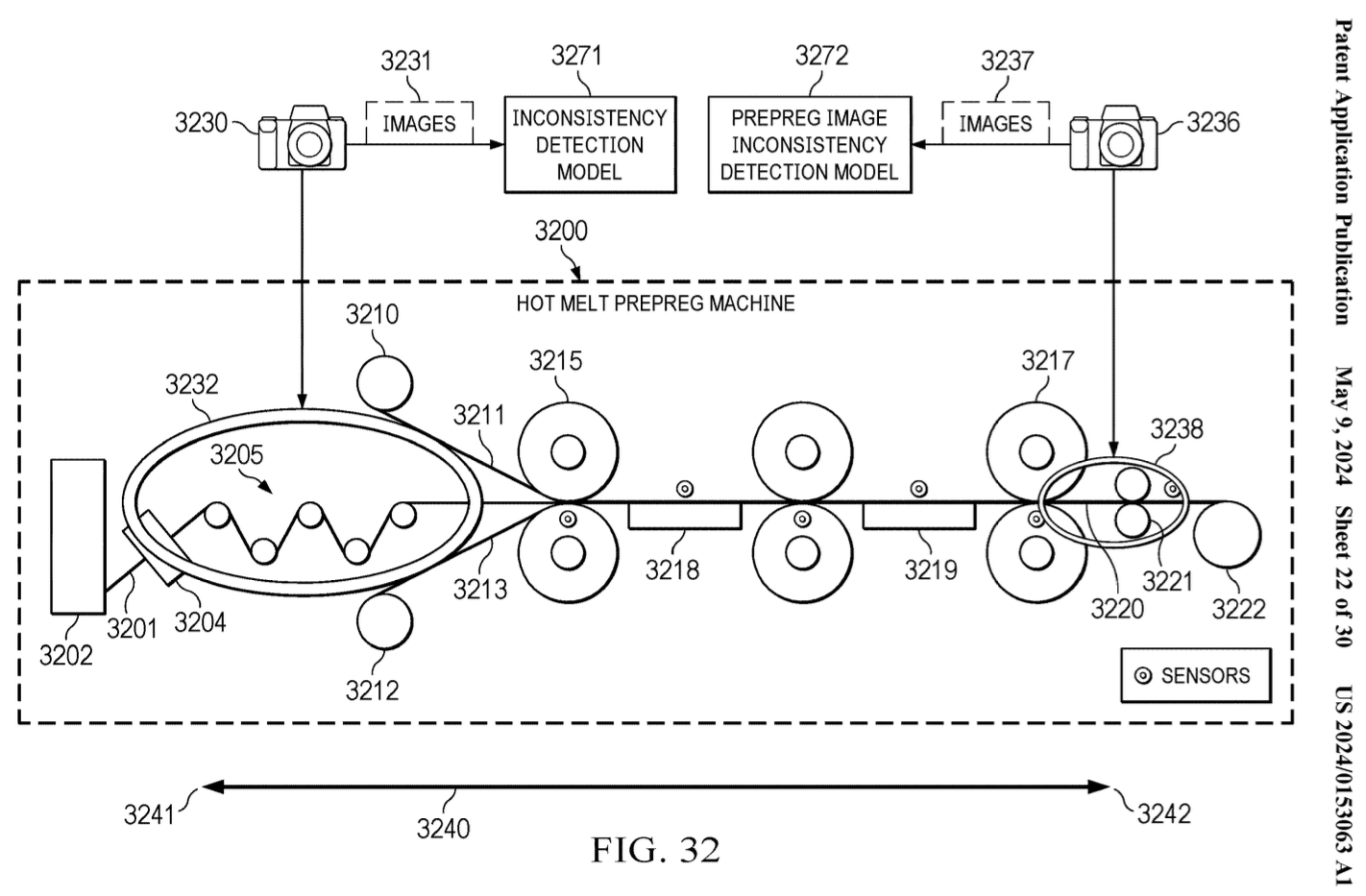

- Developed & iterated on a system of 3 cameras & 20+ in-line sensors to enable multivariate visibility into Prepreg composites

manufacturing, to ultimately decrease supply chain lead times from months to days and reduce material costs by ~20%

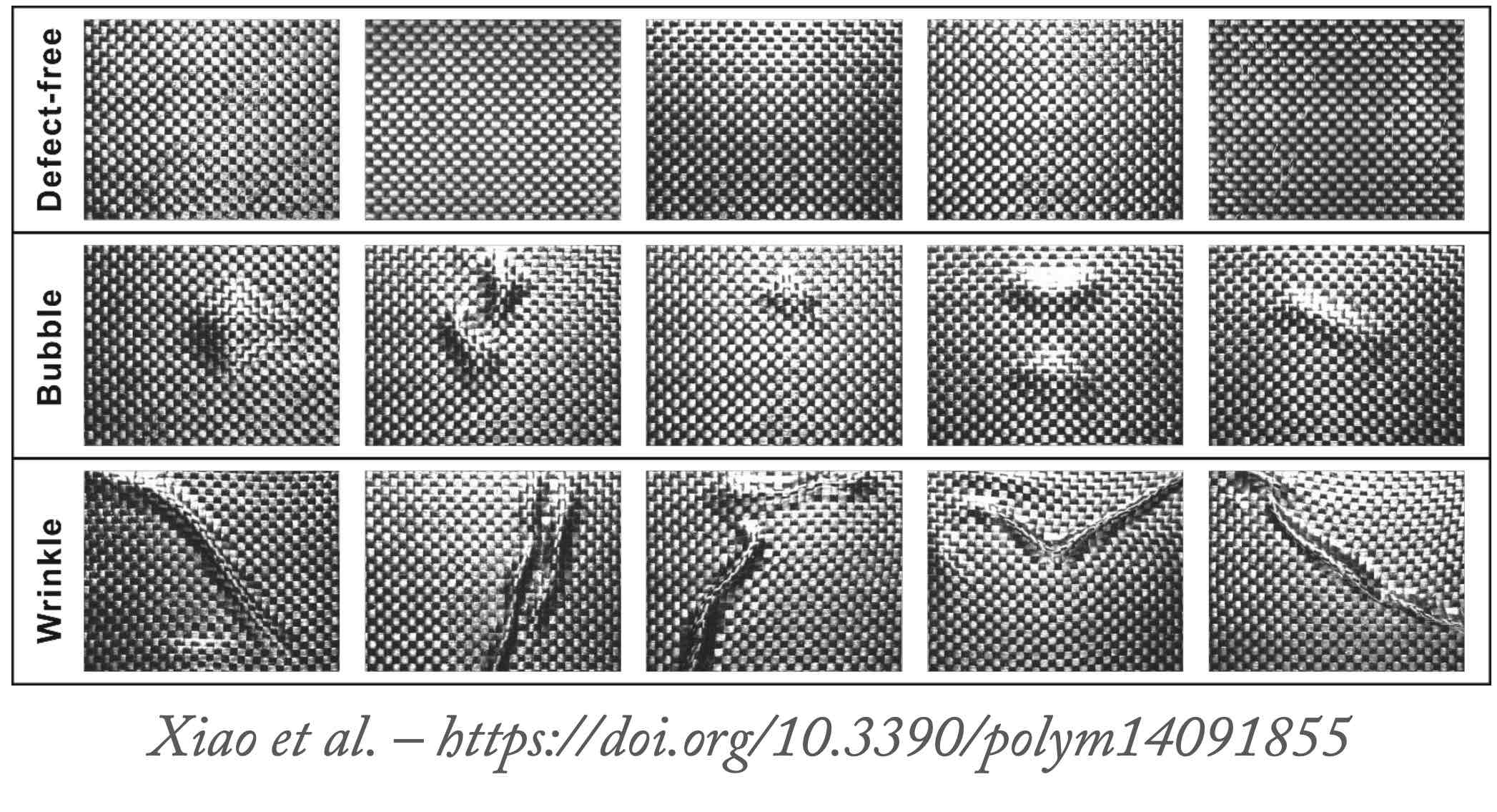

- Developed and trained a YOLOv5 machine vision model to accurately recognize 9 types of material defects, which, once

implemented, will save manufacturers thousands of dollars in scrapped material and production line down-time

- Prepared slide decks and presented technical progress and budget updates to our customers at Boeing, and used feedback to

inform our next steps, with an emphasis on agile development

- Designed custom fixtures in SolidWorks (CAD) to outfit a composites manufacturing line with a suite of sensors and cameras to enable the live readout, collection, and prediction of key material properties during the manufacturing process

- Coded and maintained a data acquisition system and analysis programs in MATLAB to collect and analyze millions of data points to investigate the effects of changing manufacturing parameters on final material characteristics

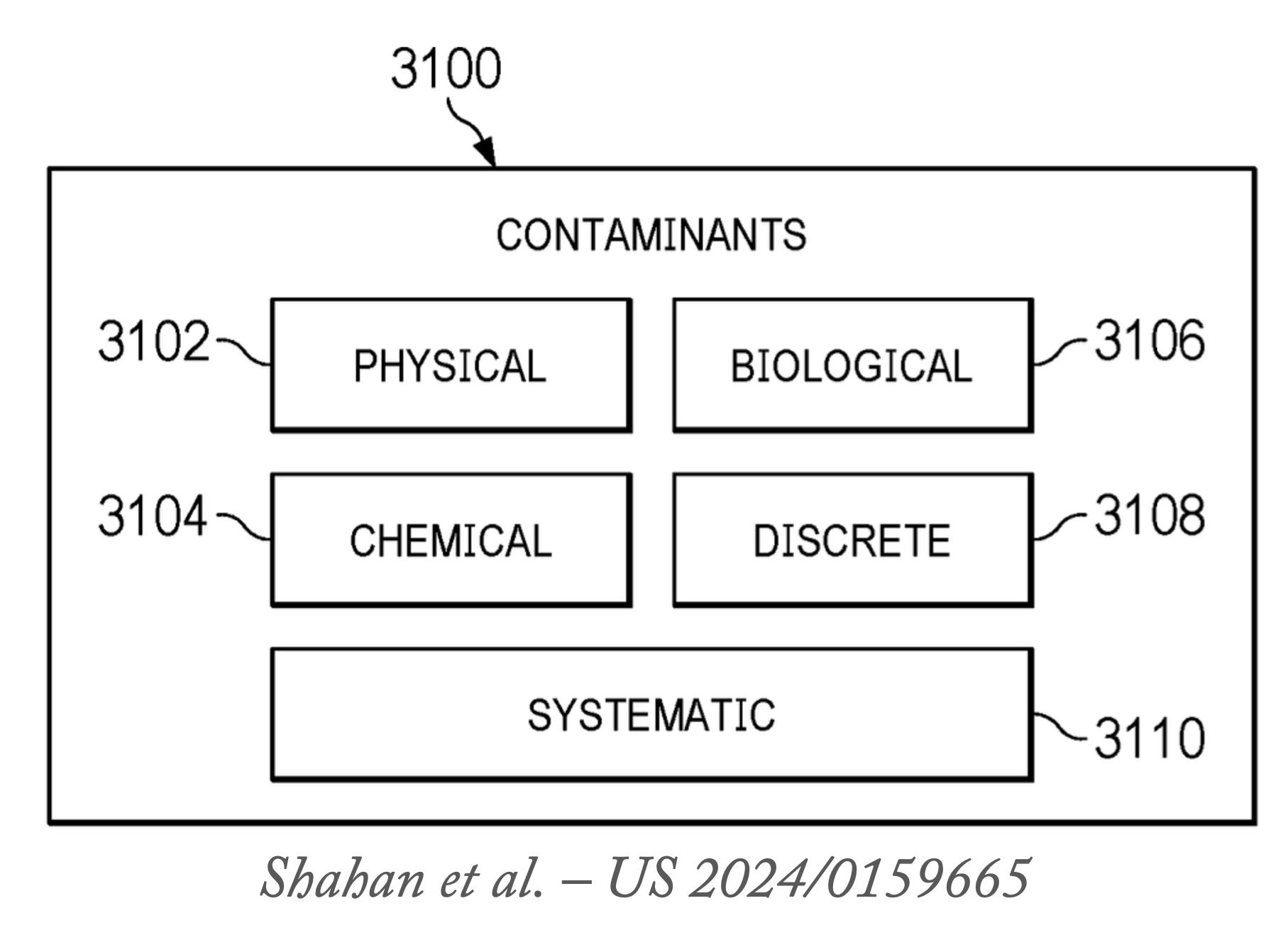

- Designed experiments to characterize the behavior of specific machine parameters, to be added to the digital twin model

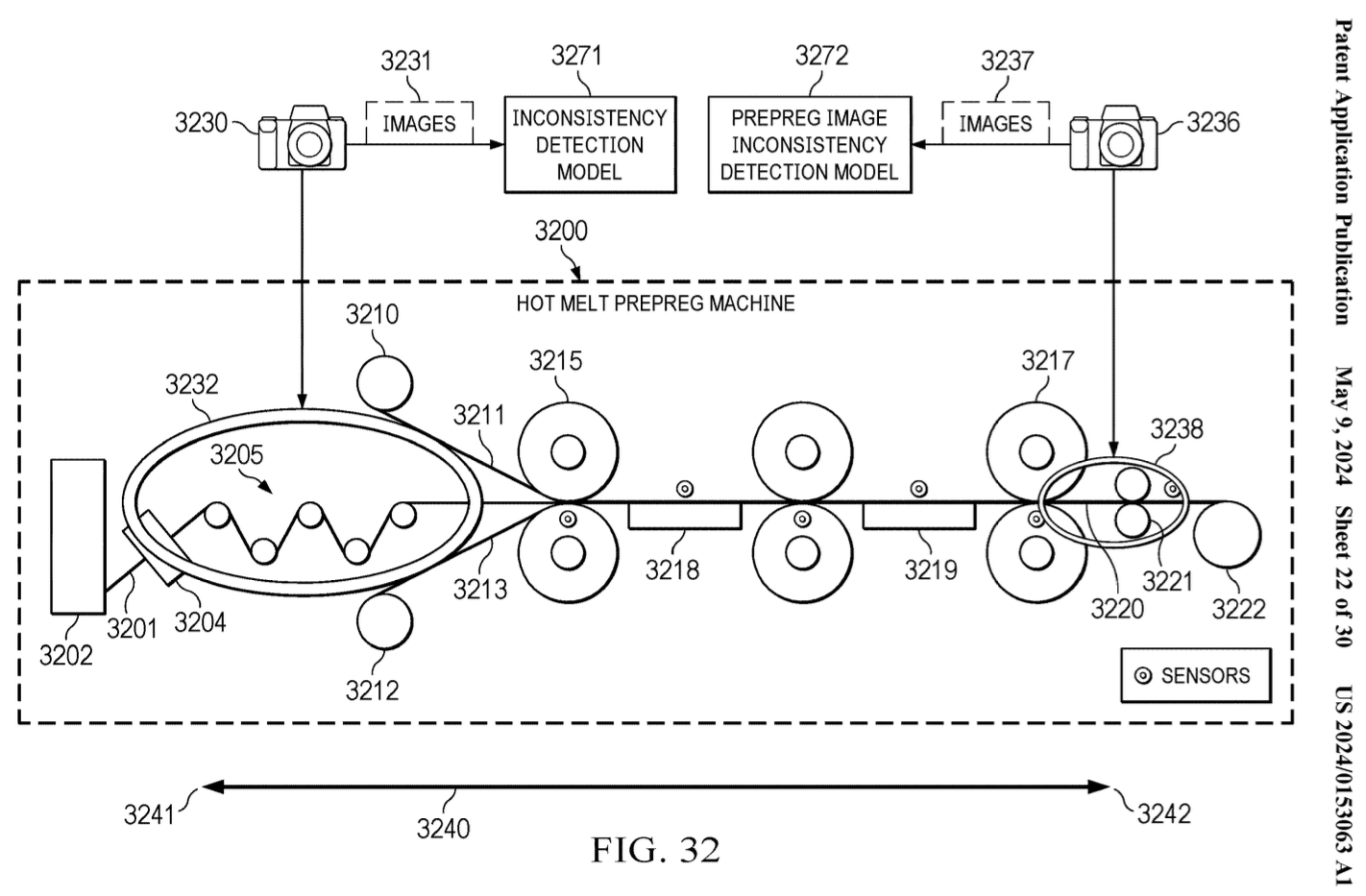

Block diagram of the Prepreg manufacturing machine with locations of sensors & cameras

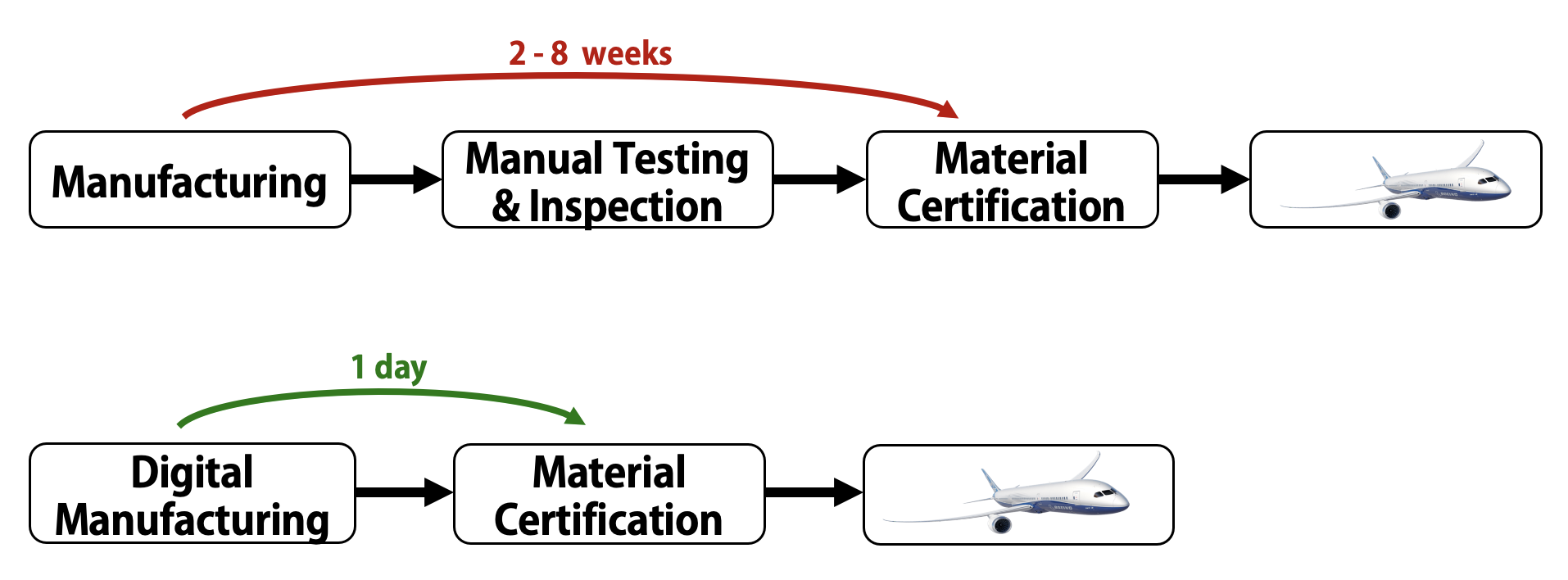

Diagram showing timeline advantages of digital manufacturing over traditional manufacturing methods

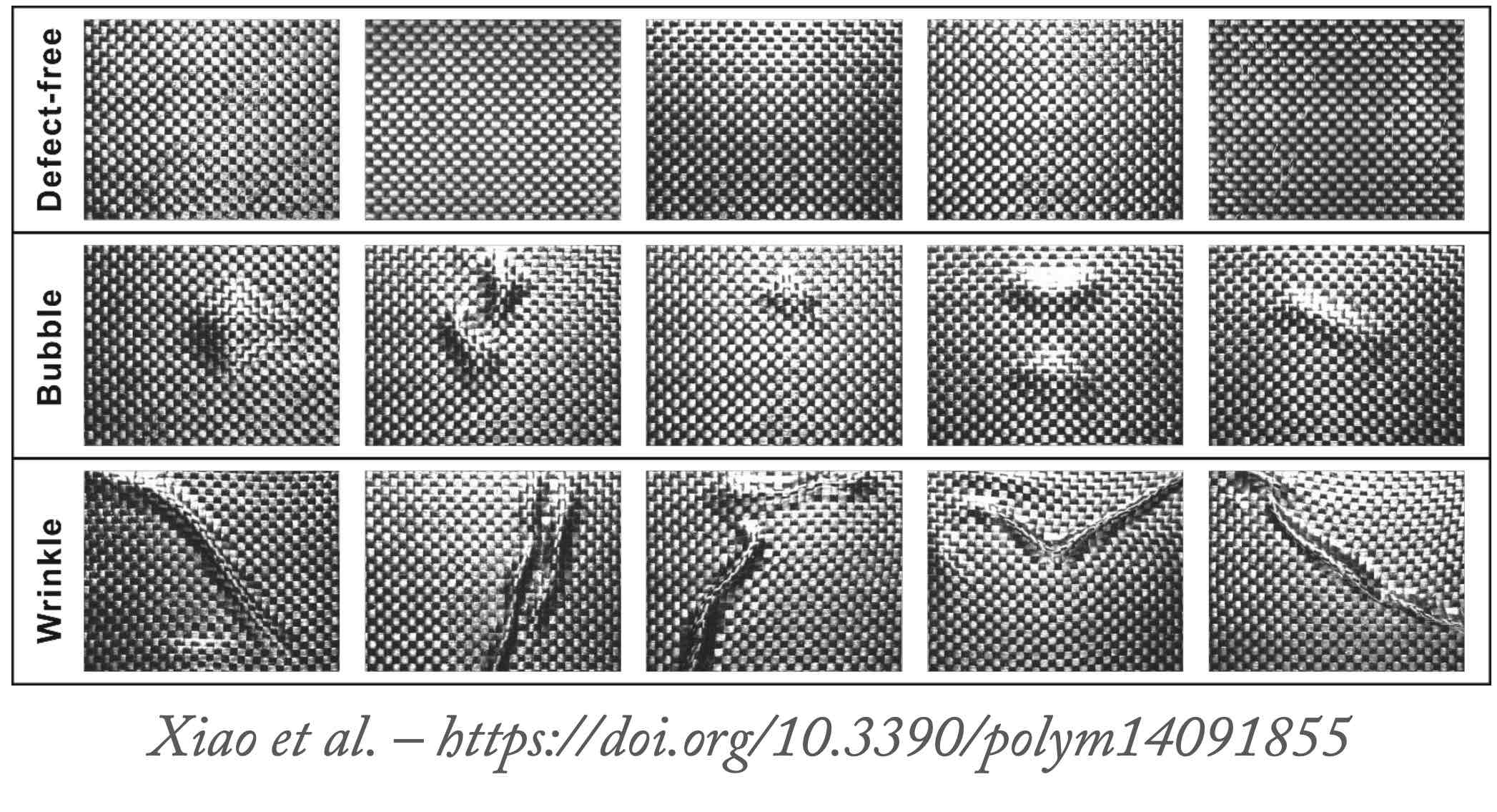

Defects commonly seen in prepreg carbon fiber – can be automatically detected by machine vision model

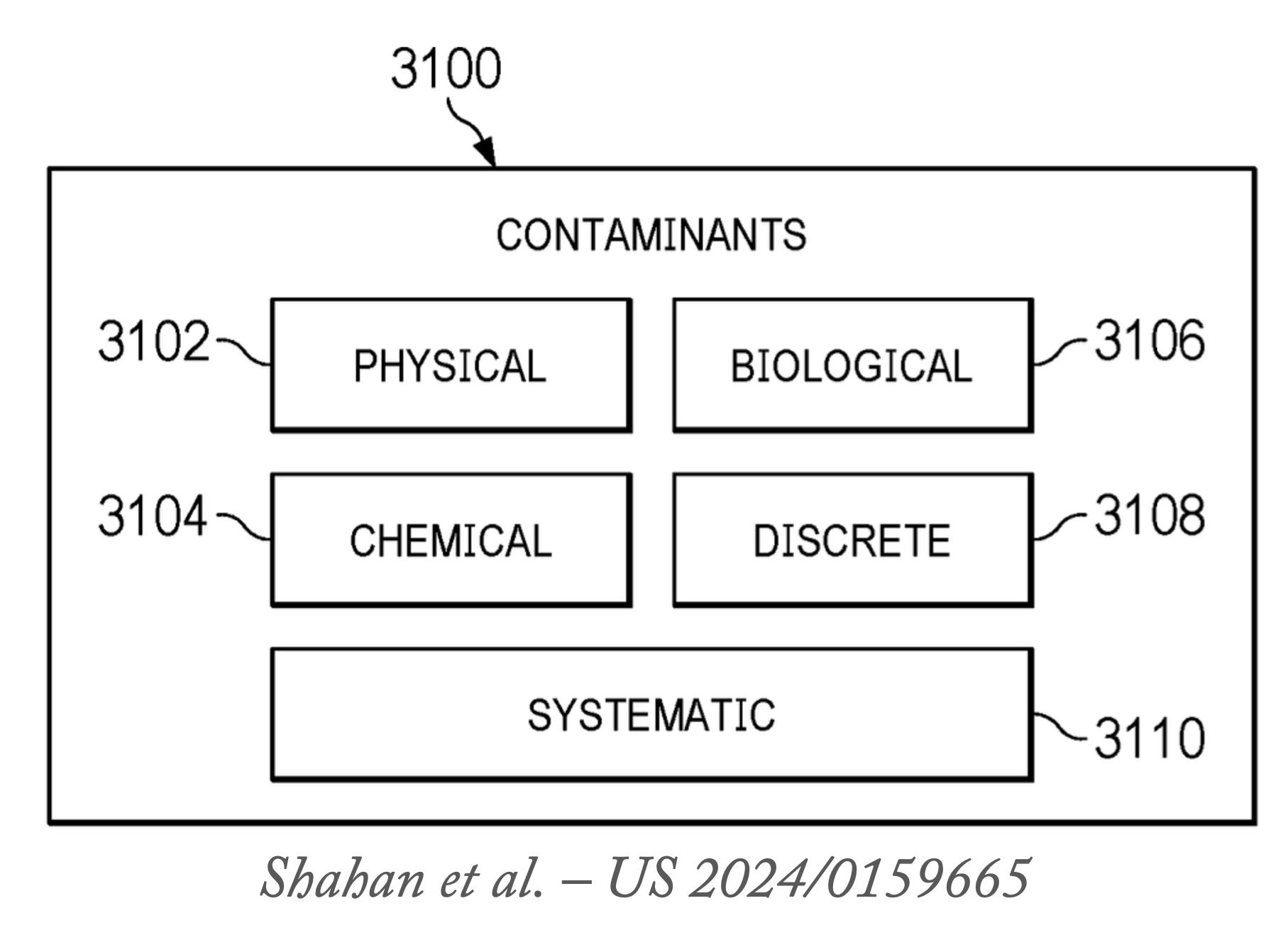

Chart showing classes of defects present in Prepreg manufacturing