CUAir is an interdisciplinary student-run project team that designs, builds, and tests a fully autonomous search-and-rescue aircraft. We compete in the AUVSI SUAS competition each summer, and currently have the top-ranked fixed-wing aircraft in the United States.

I'm on the Structures & Payloads subteam, which designs and manufactures the mechatronic components of the aircraft system. Recent subteam projects include the camera gimbal, landing gear, motor mounts, Unmanned Ground Vehicle, and the aircraft's internal structures.

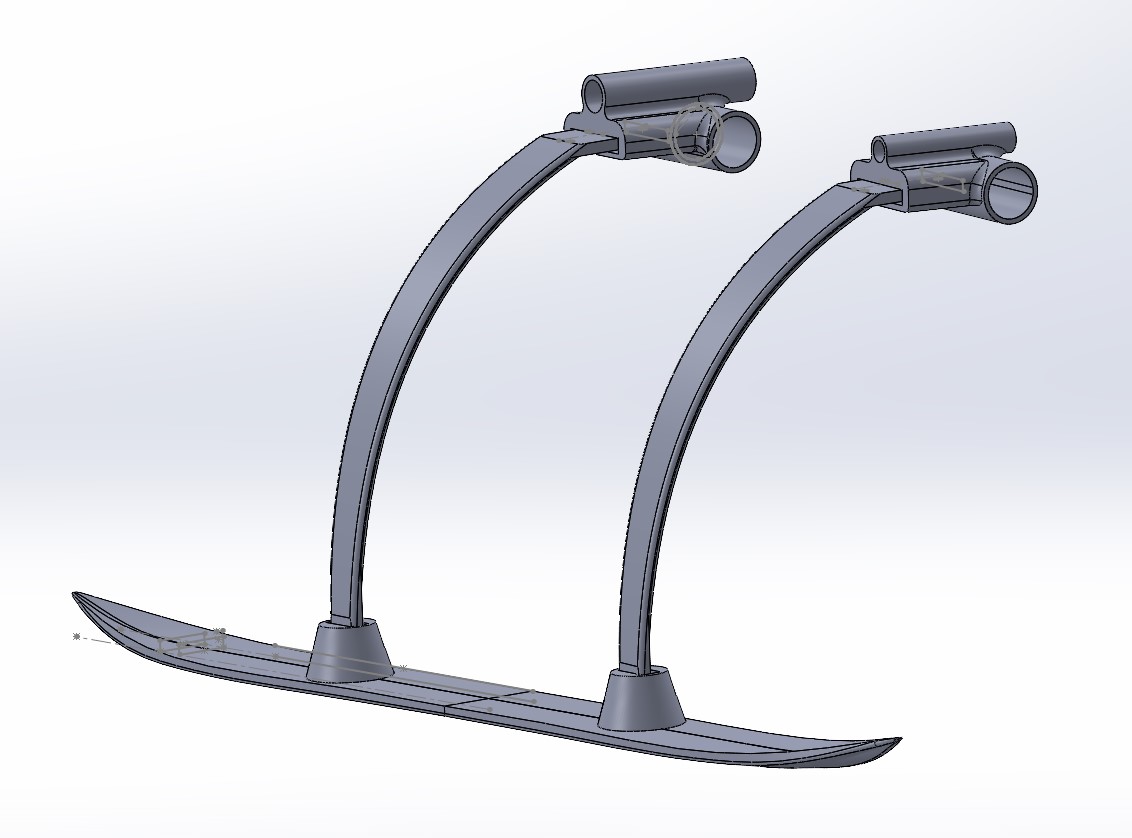

Most of the design was already complete for the landing gear, so we focused on manufacturing. The landing gear is made up of three components: the struts, the ski-to-strut connectors, and the skis.

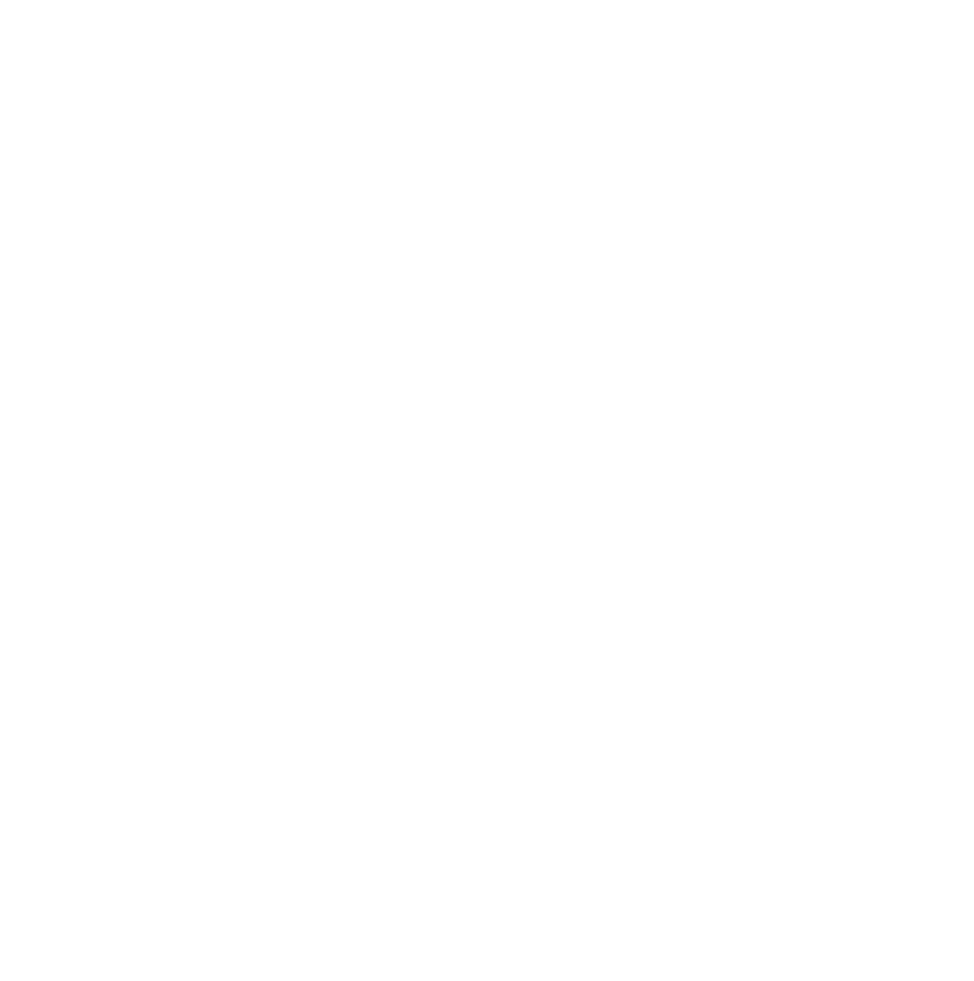

We opted to manufacture the four ski-to-strut connectors using 3D printed PVA molds filled with chopped graphite and epoxy. This allowed us to manufacture a strong, lightweight part with complex geometry relatively quickly and easily.

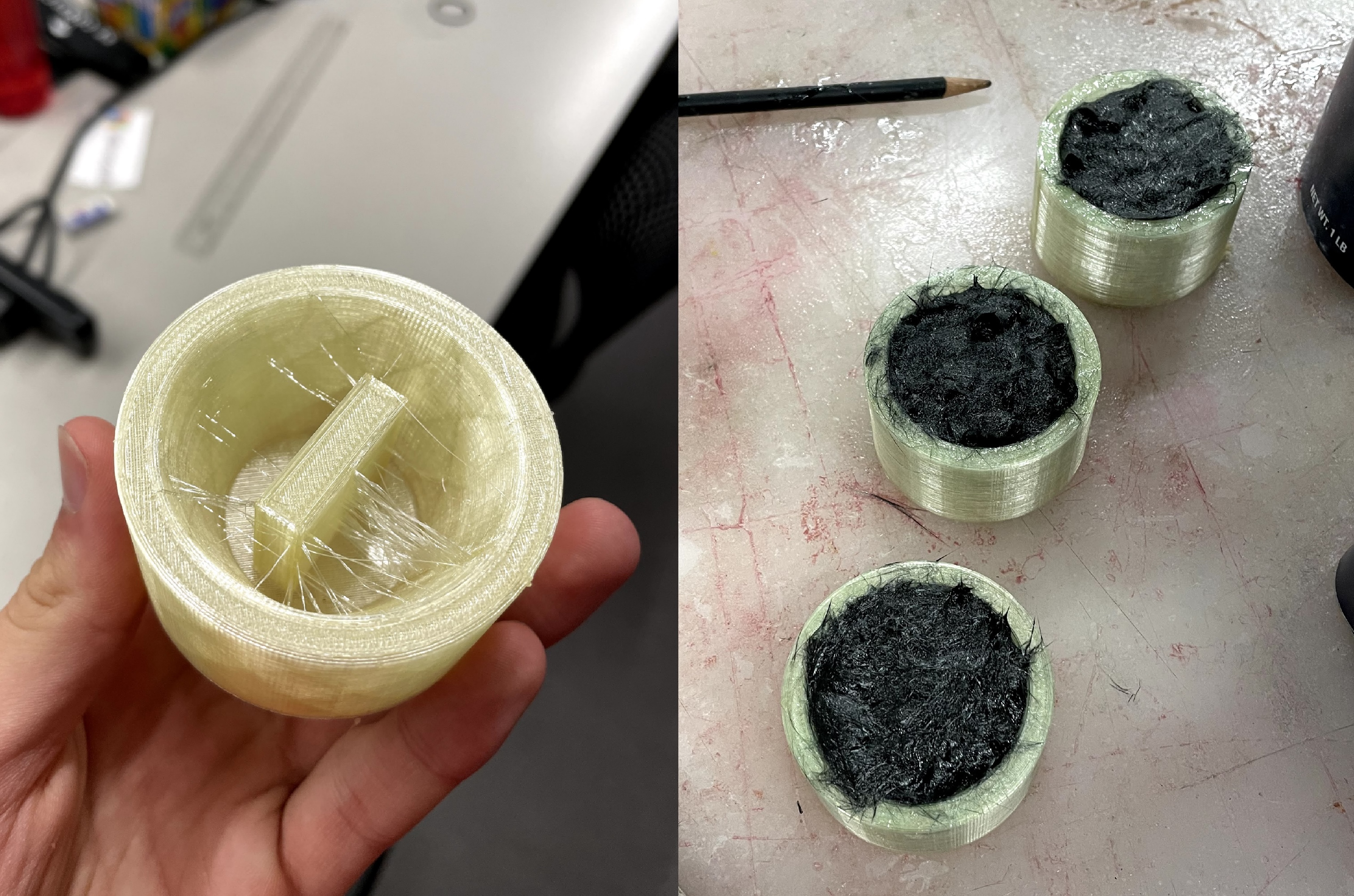

For the two skis, we 3D printed a mold out of PLA in which performed a wet layup to form the skis. Between the top and bottom layers of carbon fiber, there is a 3mm birch wood core, and the tips are reinforced with two extra layers of carbon fiber.

To assemble the landing gear components, we epoxied the pre-fabricated struts into the ski-to-strut connectors, and screwed the ski-to-strut connectors to the skis.

Fully assembled Artemis ready for take-off

Finished landing gear assembly

Manufacturing the strut-to-ski connectors using carbon fiber and epoxy casting in PVA molds

Finished ski-to-strut connectors, and testing the assembly.

Left: PLA ski mold

Right: Finished ski

Ski layup in progress

Right half of landing gear assembly CAD

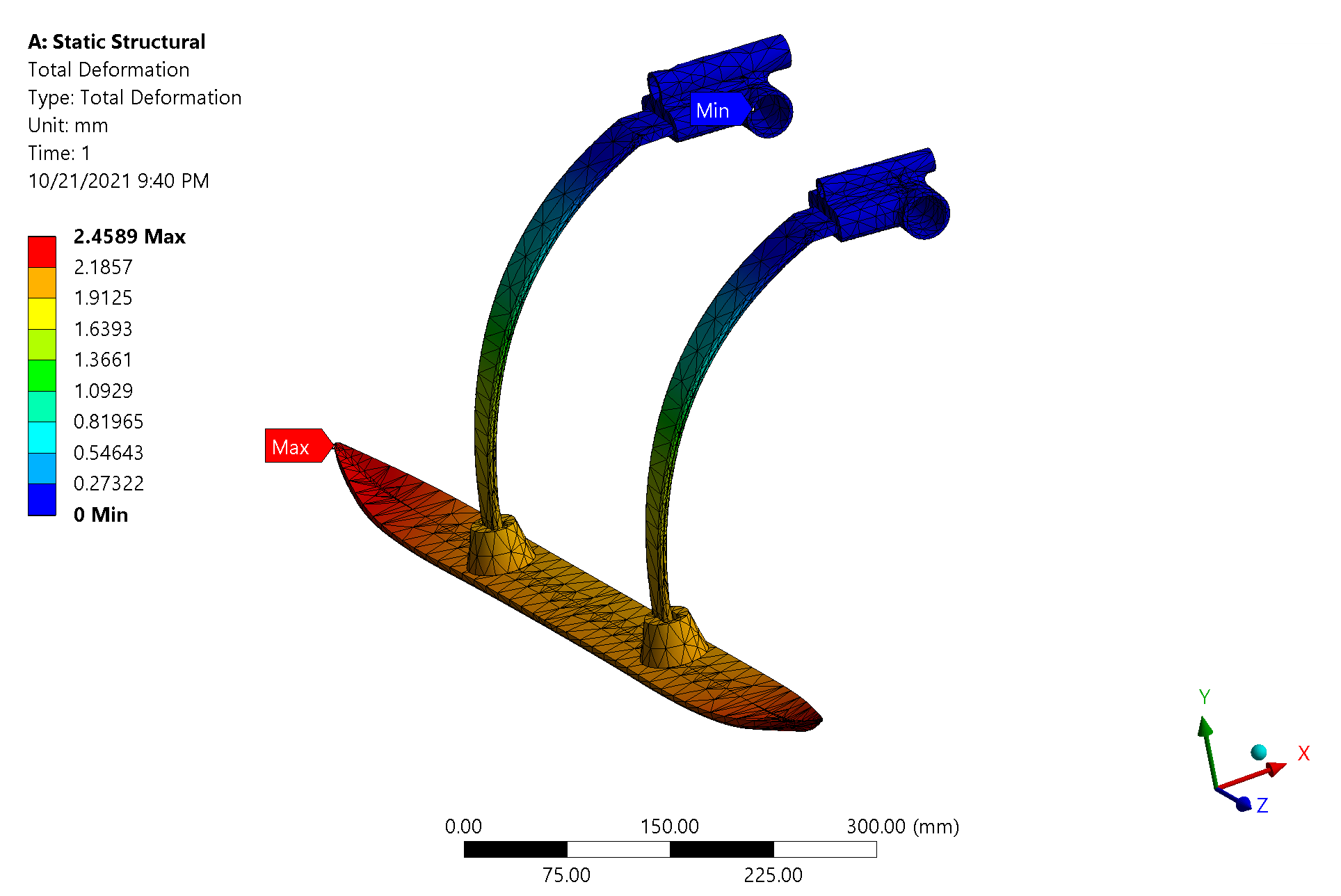

ANSYS deformation analysis